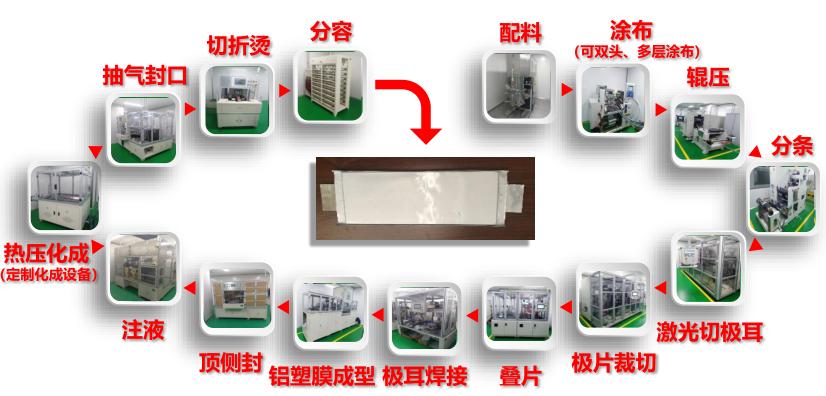

Lithium Battery Production Process

1

1

Important processes that affect battery quality and consistency:

Mixing, coating, drying, rolling, laser cutting, electrolyte filling, etc.;

These processes involve multiple simulation challenges such as non-Newtonian fluids, particles, turbulence, chemical reactions, phase changes, microfluidics, etc.

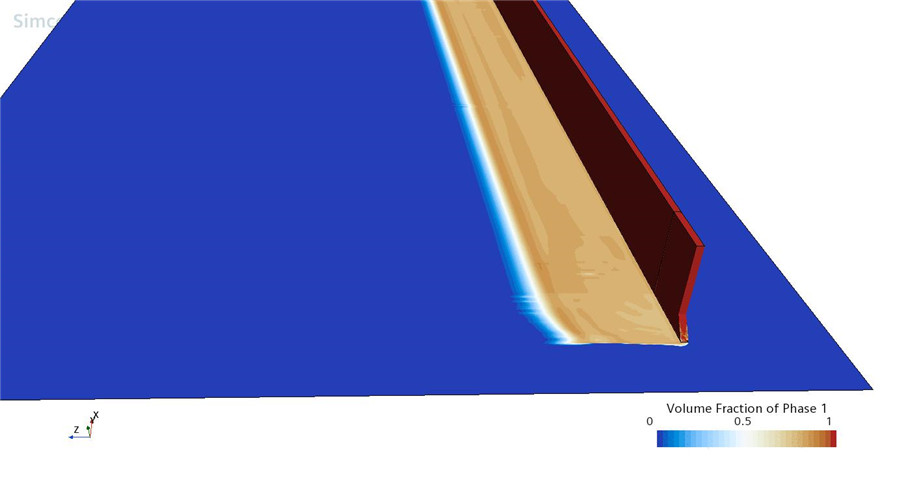

Slurry Coating

Physical Models:

Transient Analysis

Laminar Flow

Eulerian Multiphase Flow:

Slurry: Non-Newtonian Fluid Carreau-Yasuda Model

Air: Constant Density Fluid

Interphase Interaction: Surface Tension

Volume of Fluid (VOF)

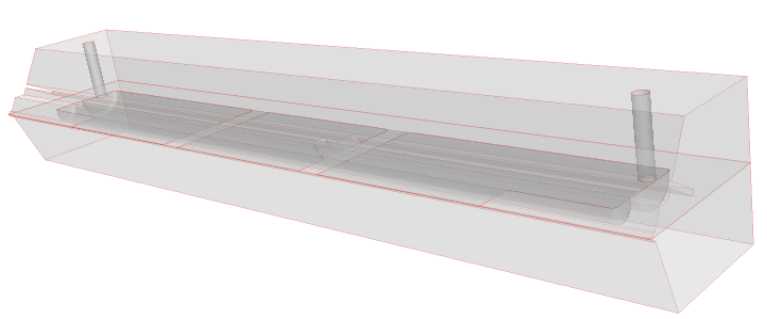

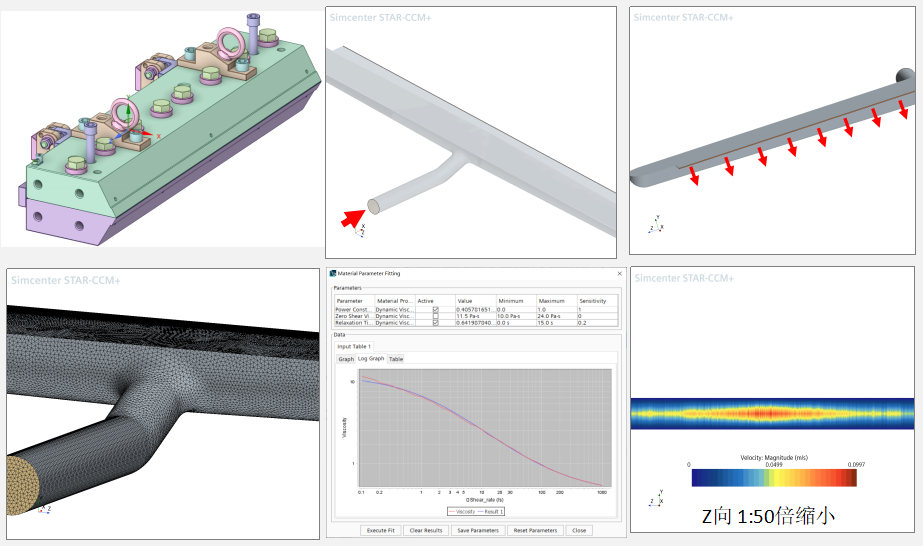

Slurry Extrusion

A CFD simulation is conducted to analyze the flow conditions of the slurry inside the coating die, focusing on the flow distribution at the slit outlet. The goal is to optimize the opening size at different positions to achieve a uniform flow distribution at the slit outlet.

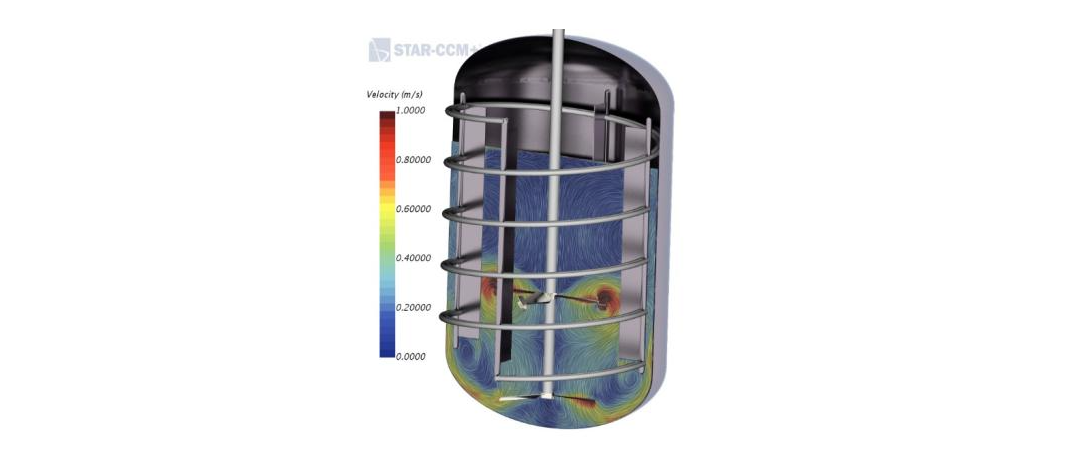

Physical Models:

Steady-State Analysis

Laminar Flow

Viscous Flow:

Viscosity: Non-Newtonian Fluid Carreau-Yasuda Model

Fitting Curve Derived from Rheological Curve Fitting

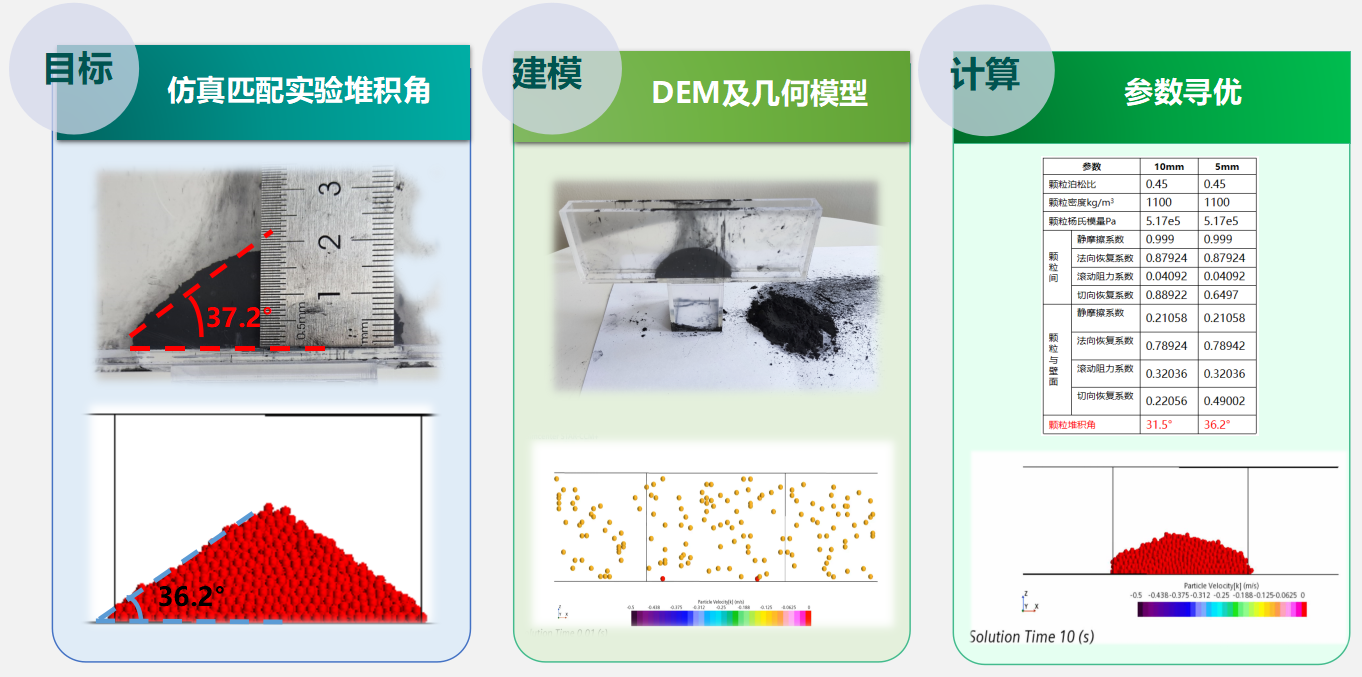

Particle Packing Simulation

Detail

Detail