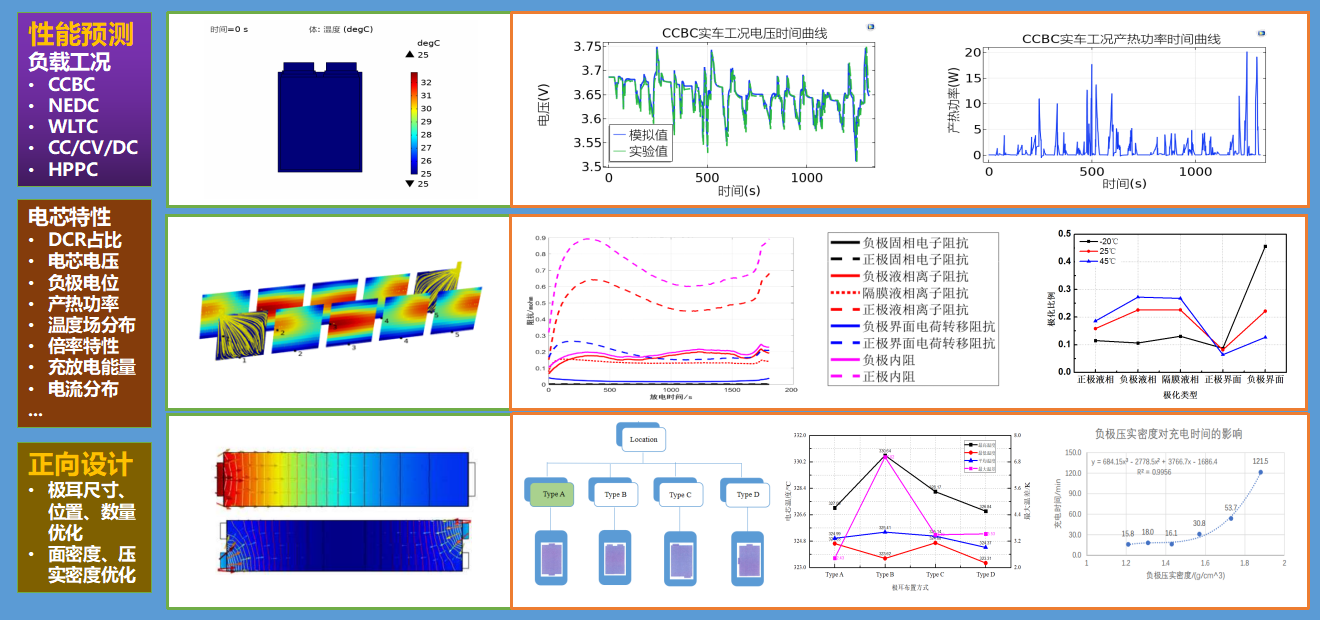

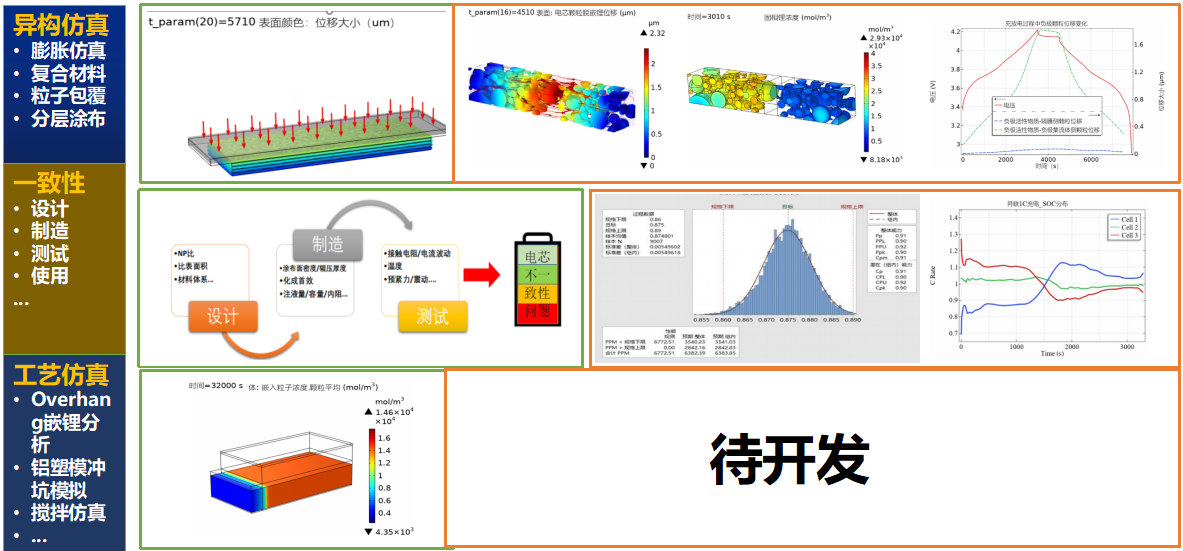

Routine Performance Simulation

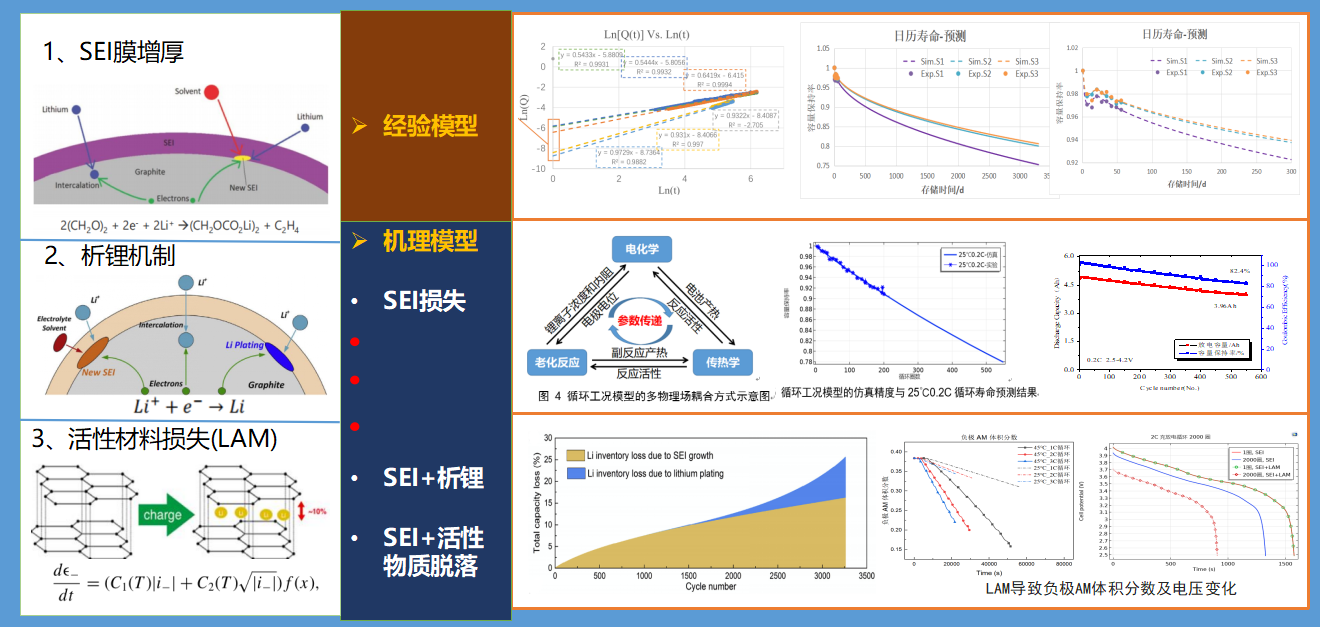

Lifespan Simulation

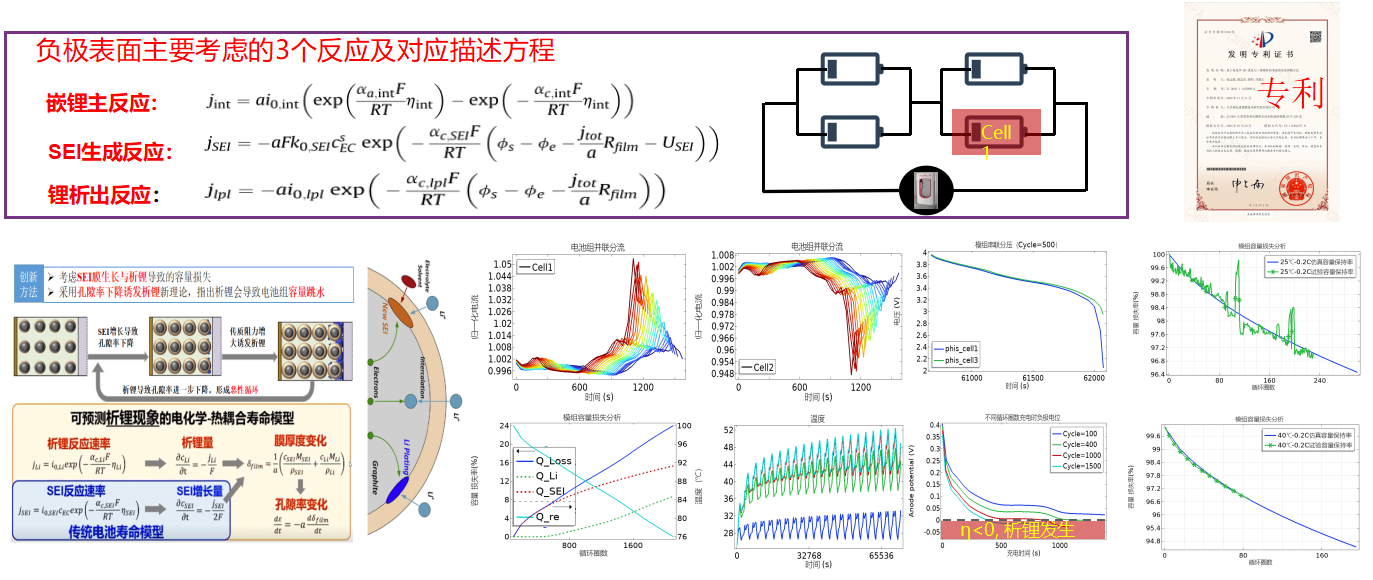

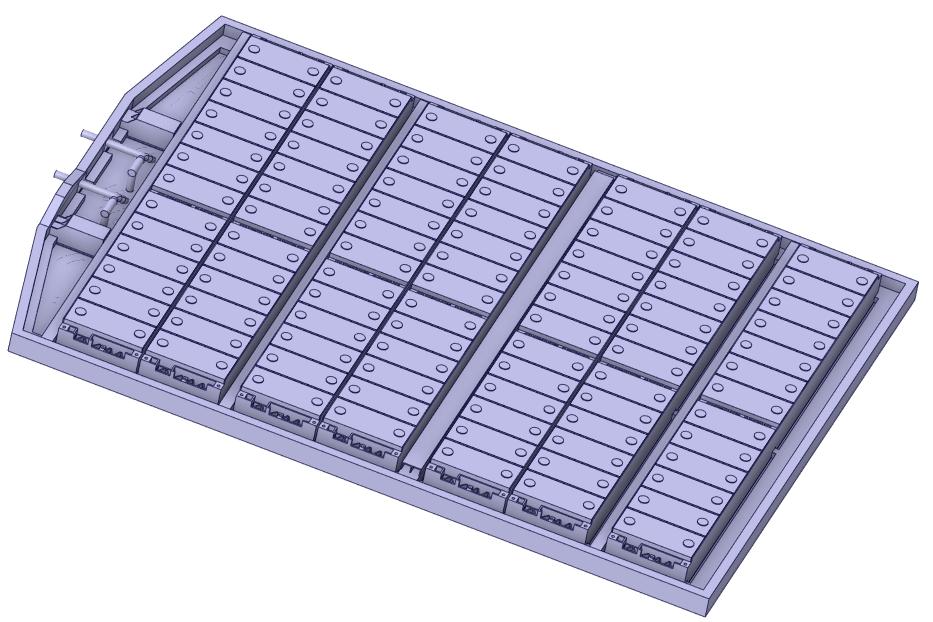

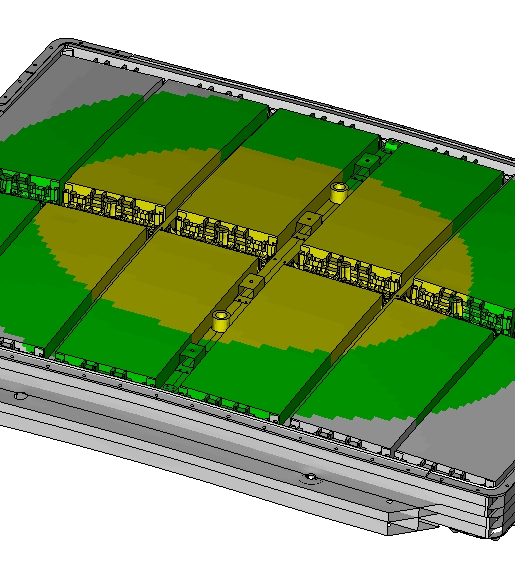

Example of Module Lifespan Simulation

Research Achievement: Completed the construction of an electrochemical model for module lifespan prediction, capable of forecasting aging caused by series voltage division, parallel current division, and temperature differences.

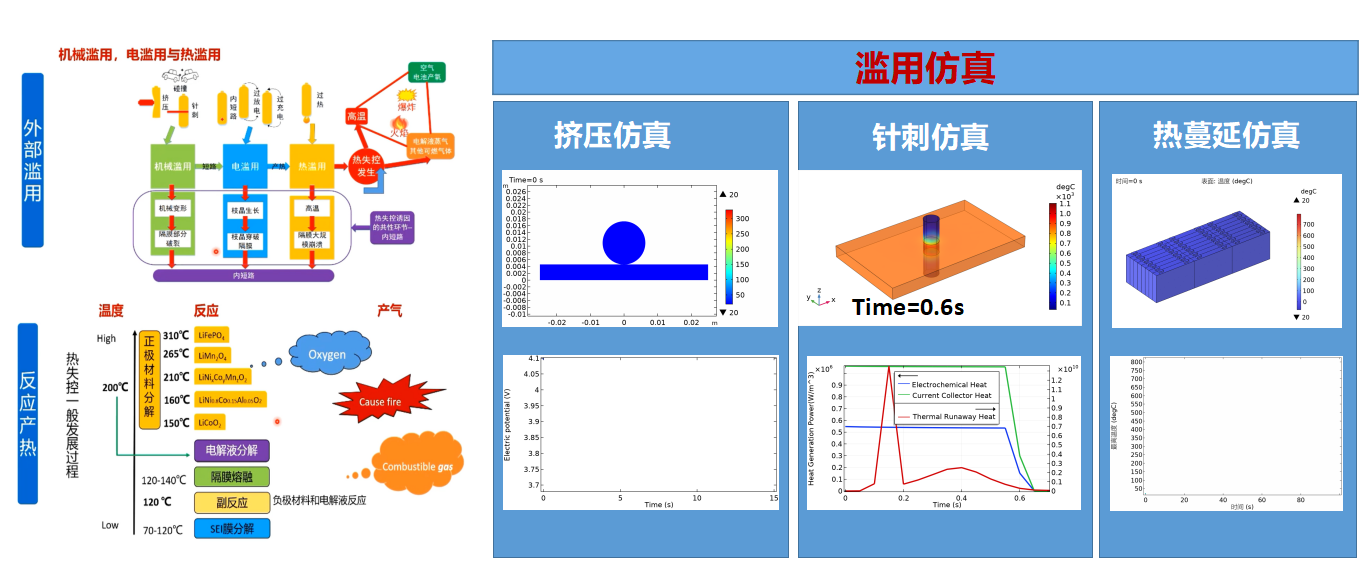

Safety Simulation/Abuse Simulation

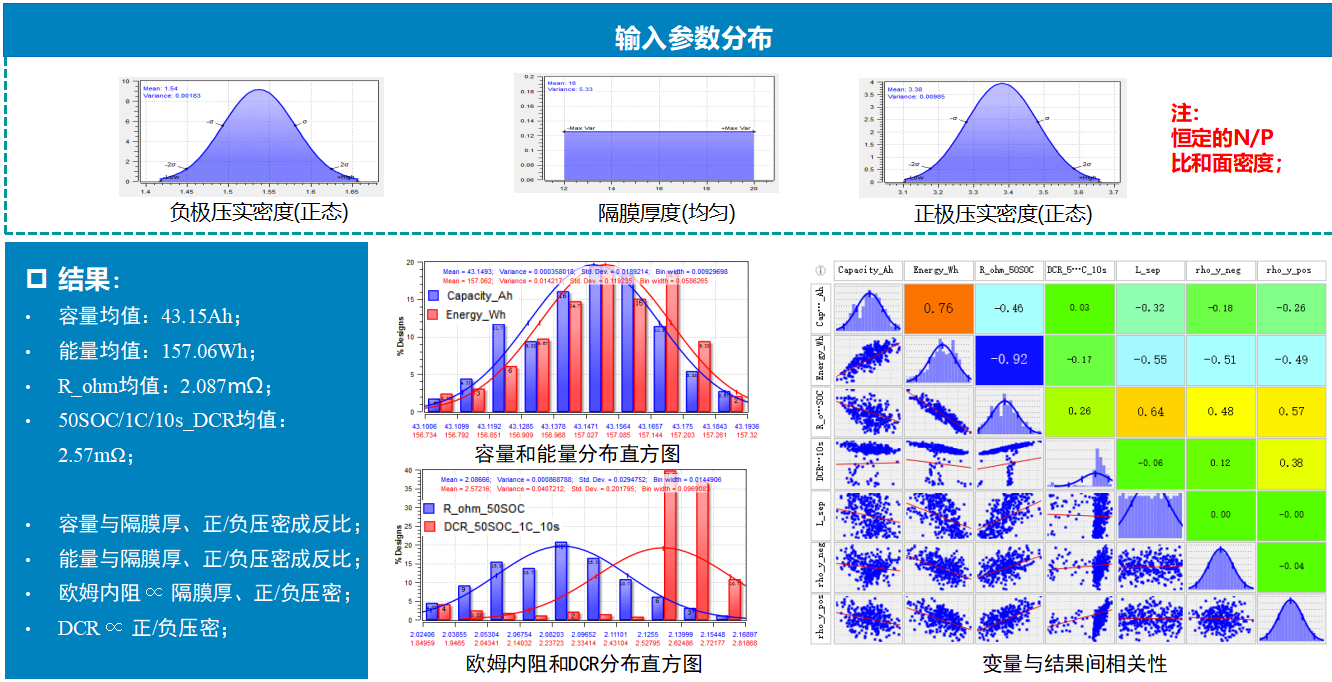

Electrochemical Performance Optimization Simulation

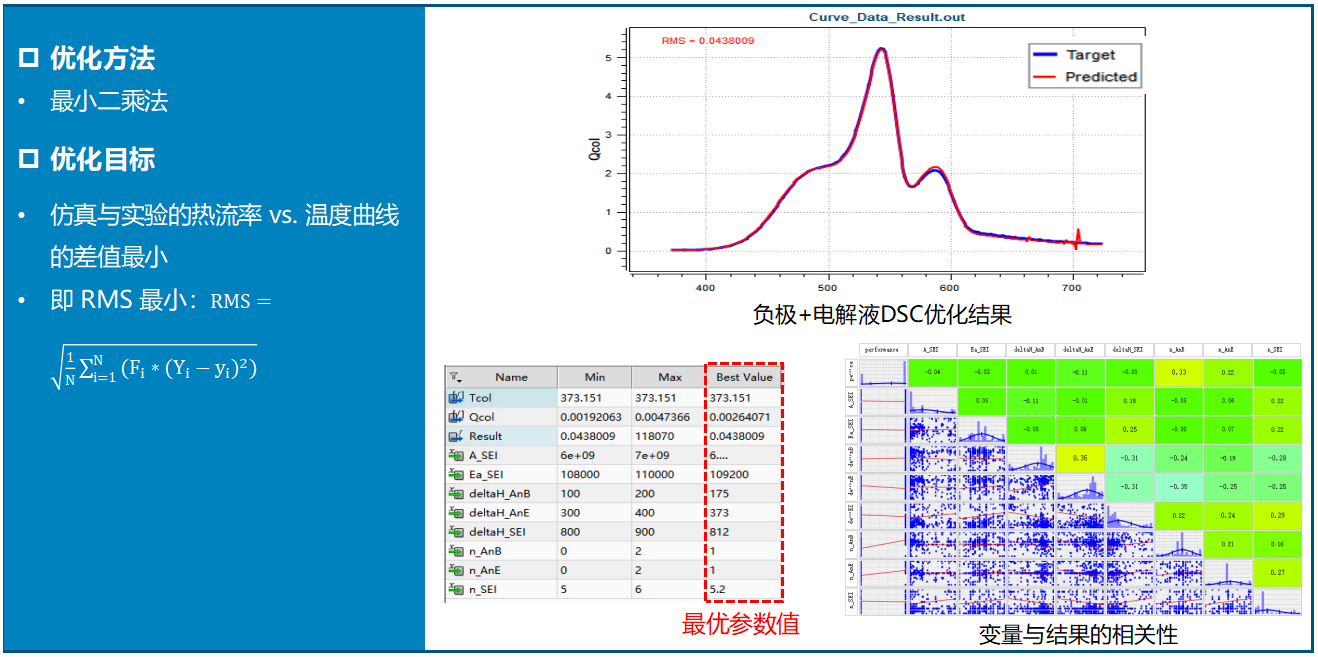

Thermal Runaway Side Reaction Parameter Optimization Simulation

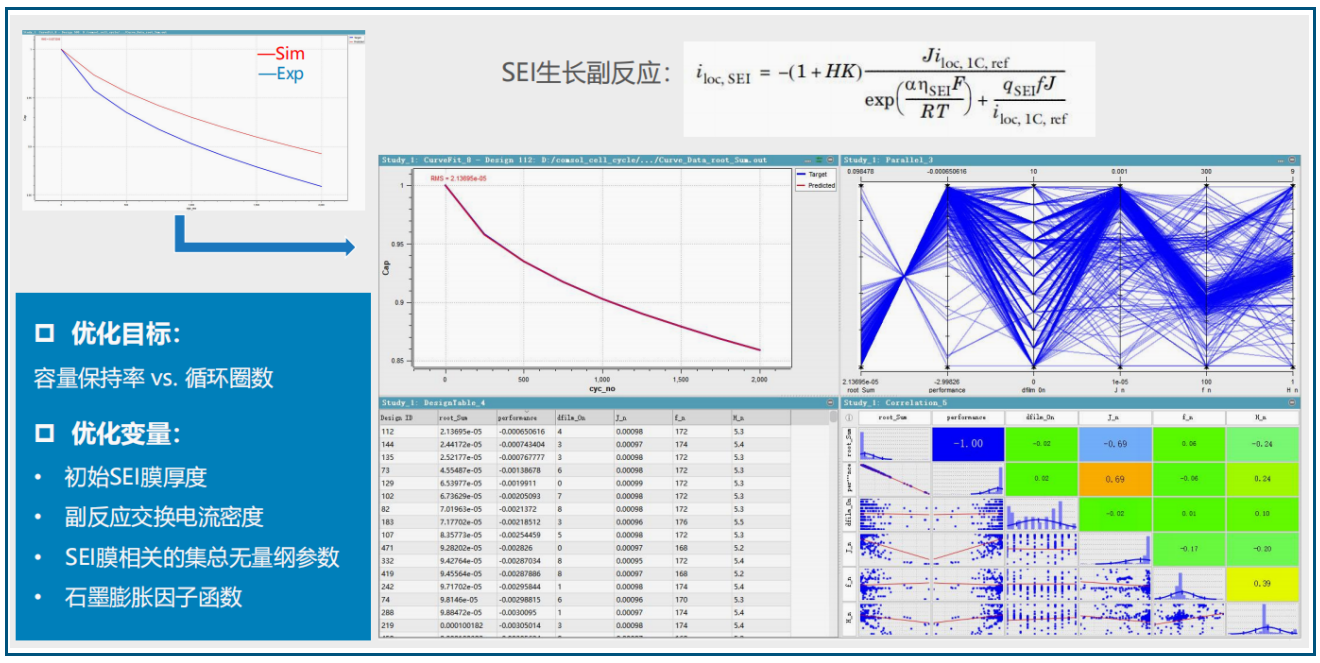

Cell Lifespan Optimization Simulation

Detail

Detail